introduce:

where we delve into the interesting world of HDPE geomembrane plants and uncover the secrets behind their exceptional output. In this article, we will explain the production process, the key factors affecting factory output and the importance of HDPE geomembranes in various industries. So, let’s embark on this journey of enlightenment together!

1. Understand HDPE geomembrane:

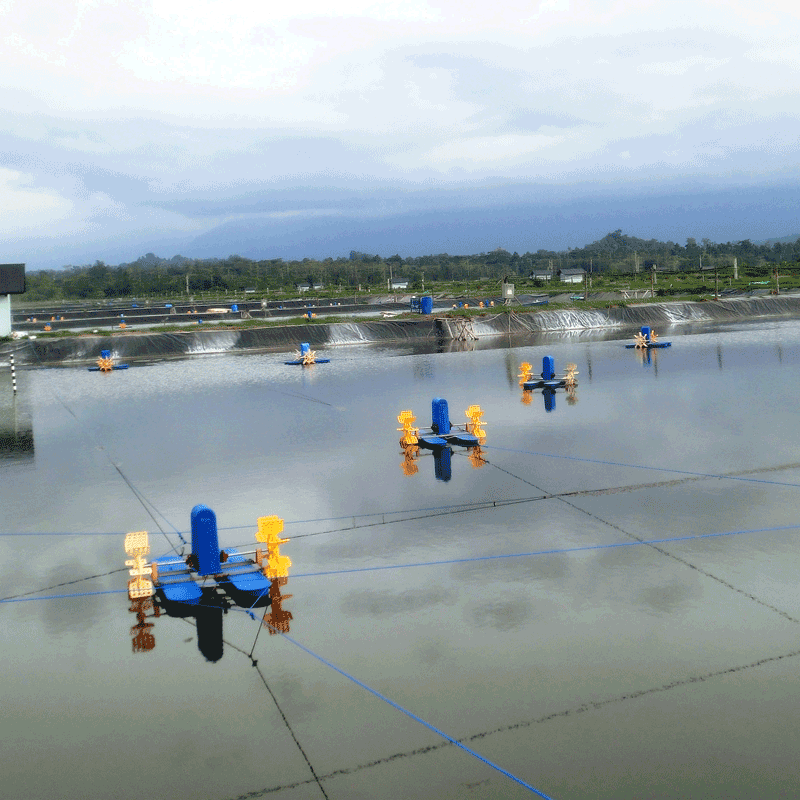

HDPE (High Density Polyethylene) geomembrane is an impermeable synthetic liner used in a variety of applications including landfills, mining, agriculture, pond liners and containment systems. Its exceptional qualities, such as high chemical resistance, durability and flexibility, make it ideal for these industries.

2. Production process:

Manufacturing high-quality HDPE geomembranes requires a meticulous production process. First, the raw materials are carefully selected to ensure they meet the required specifications. The selected HDPE resin is manufactured through a series of processes including extrusion, calendering and lamination. The modern factory uses advanced machinery and equipment and adopts strict quality control measures to ensure stable output.

3. Key factors affecting factory output:

a) Technological advancement: HDPE geomembrane plants investing in cutting-edge technology and machinery may achieve higher output. Automation, state-of-the-art extrusion lines and advanced quality control systems streamline the manufacturing process, ultimately increasing factory output.

b) Skilled Labor Force: Well-trained and experienced labor force plays a vital role in achieving optimal factory output. From operating machines to managing quality control, skilled personnel help make the production process smoother and minimize the occurrence of errors or defects.

c) Procurement of quality raw materials: The quality and composition of the raw materials have a great impact on the final product. HDPE geomembrane factories give priority to purchasing high-quality HDPE resin to ensure better output and meet the strict standards of the industry.

d) Efficient time management: Effective scheduling and production planning are key to maximizing factory output. The HDPE geomembrane factory implemented efficient time management strategies, including optimizing shifts, reducing machine downtime and implementing lean management principles, resulting in a significant increase in output.

4. The significance of HDPE geomembrane:

HDPE geomembranes play a vital role in protecting the environment and ensuring the long-term stability of many industries. By acting as a barrier against the leakage of harmful substances, it protects ecosystems, groundwater sources, and human health. In addition, its exceptional durability ensures longevity and reduces life cycle costs, making it a cost-effective solution for specific industry applications.

in conclusion:

we explore the fascinating world of HDPE geomembrane production and the factors that lead to significant plant output. From understanding the production process to recognizing the importance of HDPE geomembranes, we shed light on various aspects related to this important material. As technological advancements continue to impact the industry, HDPE geomembrane factories around the world are constantly working to increase production to meet the growing demand for this versatile material.

Post time: Oct-30-2023