-

PET Short Filament Nonwoven Geotextile

PET short filament geotextile is manufactured using an advanced manufacturing and quality system which produces greatly uniform and consistent nonwoven needle-punched geotextile in the industry. Yingfan combines a fiber selection and approval system with in-line quality control and our laboratory to ensure that every roll shipped meets customer and application specifications.

-

Geomembrane Geotextile Composites

Our geomembrane geotextile composites product is heat-bonded by filament nonwoven or staple fiber nonwoven geotextile to PE geomembranes. It has excellent anti-seepage and flat drainage characteristics.

-

Geotextile Geomembrane Composites

Our geotextile geomembrane composites product is laminated geomembranes to nonwoven geotextiles. The composites combine the functions and advantages of both the nonwoven geotextile and geomembrane.

-

Plastic PP Woven Film Yarn Geotextile

Our supplied plastic polypropylene woven film yarn geotextile is made by pp resin extrusion, splitting, stretching and weaving processing ways. The process creates geotextiles featuring high tensile strengths with low elongation. These characteristics make it an excellent choice for soil separation, stabilization and reinforcement applications.

-

PP Short Filament Nonwoven Geotextile

PP short filament nonwoven geotextile is manufactured by 100% polypropylene (PP) staple fiber. Its processing way includes short fiber material carding, lapping, needle punching, being cut and rolled.

-

Composite Geomembrane

Our Composite Geomembrane ( Geotextile-Geomembrane Composites) is made by heat-bonding a nonwoven geotextile to geomembranes. The composite has functions and advantages of both the geotextile and geomembrane. The geotextiles provide increased resistance to puncture, tear propagation, and friction related to sliding, as well as providing tensile strength in and of themselves.

-

Staple Fiber PP Nonwoven Geotextile

Staple fiber PP nonwoven geotextile is made from 100% high strength polypropylene (PP) short fiber. Its processing way includes short fiber material carding, lapping, needle punching, being cut and rolled. This permeable fabric has the properties to separate, filter, reinforce, protect, or drain. Compared with staple fiber PET nonwoven geotextile, PP geotextile has higher mechanical strength. PP material itself has superior chemical resistance and heat endurance properties. It is an eco-friendly construction material.

-

Plastic Welding Vacuum Tester

The plastic welding vacuum tester is mainly used to test the welding quality, welding effect and accurate positioning of leaking points on the parts where inflation testing cannot work or welding rods have been applied to repair shortage and leakage at planar construction sites.

-

PET Filament Nonwoven Geotextile

PET filament nonwoven geotextiles are continuous sheets of nonwoven fibers. The sheets are flexible and permeable and generally has the appearance of a fibric. They are made from 100% polyester (PET) continuous fiber without chemical additives. Geotextiles production flow is spinning, lapping and needle punched by our advanced equipment.

-

Geomembrane Supported Clay Geosynthetic Barriers

It is a geomembrane supported geosynthetic clay barrier, providing the best leak protection available in the market. Our product combines a HDPE geomembrane in a smooth surface with the swelling and sealing ability of sodium bentonite.

-

Drainage Geocomposite

Drainage Geocomposite is available in both single-sided and double-sided products with geonet core thickness from 3mm to 10mm, and fabric ranging from 100gsm to 300gsm. The non-woven geotextile is bonded to the geonet with a hot knife application, allowing for high bond strength without the reduction of transmissivity values of other processes.

-

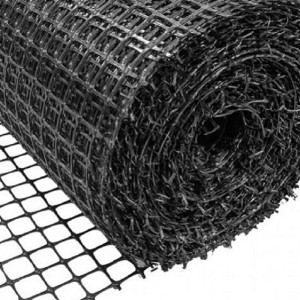

Polypropylene Biaxial Geogrids

Polypropylene biaxial geogrids are made of premium polypropylene polymer, which is extruded into a thin sheet, then punched into regular mesh in transversal and longitudinal direction. This chain netting structure can effectively bear and transfer forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.